Power Distribution In Oil-Gas Systems

Contents

Let’s explore MV-LV power distribution in Oil and Gas production facilities as well as power distribution and lighting system equipment used in environments with combustible and flammable gases. This paper addresses electrical engineers and introduces the engineering principles of air-insulated MCC and power distribution boards in environments with combustible and flammable gases.

INTRODUCTION

In Oil & Gas industry, power is distributed at MV and LV levels. As an alternative to pump jacks, crude oil is drilled using electric-driven pumps. Electric pumps may consume MV or LV power based on their ratings. Furthermore, certain amounts of chemicals are added to crude oil in order to separate water and other substances after drilling. This system consumes LV power from MCC switchboards. Since air conductivity is a problem in terms of insulation in MV and LV distribution environments, “exproof system” distribution kiosks should be designed to prevent electrical explosions. All rooms that form the distribution kiosk should be heated and cooled with an HVAC system, and insulated from outdoor air that contains combustible and flammable gases. All rooms that form the power distribution kiosk are protected against fire by means of automatic fire detection and suppression systems. Room lighting and external lighting fixtures and switches have “exproof” insulation characteristics against combustible and flammable gases. Power outlets to be used on site for maintenance should also have the same characteristics. System includes a UPS to supply power continuity-sensitive loads of the plant for 8 hours.

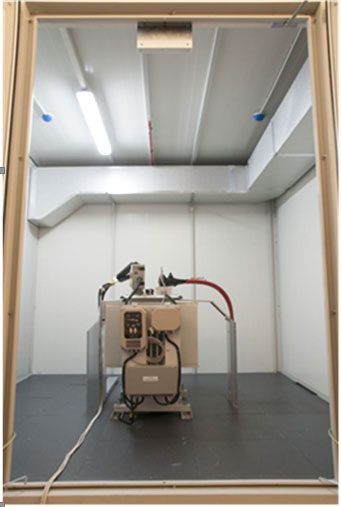

Figure 1 shows the power distribution kiosk manufactured as per the standards applicable to Oil & Gas industry. MV cubicle room consists of 4 sections namely MVLV transformer room, LV distribution and MCC switchboards, UPS switchboard room and battery room. In addition, an A/C system and an automatic fire detection and suppression system are available.

GENERAL

For power distribution centers in environments with combustible and flammable substances in oil and gas industry, electrical power is received at MV level and distributed at MV and LV levels. High-power electric motor pumps are supplied by MV power, and dosing and circulation pumps are supplied by LV power. A UPS is available for 8-hour supply to systems that should be powered continuously. Exproof equipment that withstand combustible and flammable gas environments are used for internal and external lighting equipment and power outlets,.

Standards applicable to construction of electricity distribution kiosks in environments with combustible and flammable gases in oil and gas industry

| IEC 60664 | Insulation Coordination For Equipment Within Low- Voltage Systems |

| IEC 60751 | Industrial Platinum Resistance Thermometers and Platinum Temperature Sensors |

| IEC 61000 | Electromagnetic Compatibility (EMC) |

| IEC 61537 | Cable Management – Cable Tray Systems and Cable Ladder Systems |

| IEC 61557 | Electrical Safety in Low voltage Distribution Systems up to 1000 Vac and 1500 Vdc – Equipment for Testing, Measuring or Monitoring of Protective Measures |

| IEC 62271-202 | High Voltage Switchgear and Controlgear – Part 202: High Voltage/ Low voltage Prefabricated Substation |

2.2 Construction of kiosks must comply with the following international standards.

| ISO 25 | General Requirements for Competence of Calibration and Test Labs |

| ISO 261 | ISO General Purpose Metric Screw Threads |

| ISO 3452 | Non-Destructive Testing Penetrate Inspection – General Principles |

| ISO 3453 | Non-Destructive Testing Liquid Penetrant Inspection – Verification |

| ISO 3506 | Corrosion Resistant Stainless Steel Fasteners – Specifications |

| ISO 5579 | Non-Destructive Testing Radiographic Phenomenon – Basic Rules |

| ISO 8501 | Preparation of Steel Substrates (2 Parts) |

| ISO 9013 | Welding and Allied Processes |

| ISO 10721 | Steel Structures: Materials and Design |

The following standards are applicable to selection and installation of electrical equipment

| IEC 60038 | IEC Standard Voltages |

| IEC 60079 | Explosive atmospheres |

| IEC 60885 | Electrical Test Methods for Electric Cables |

| IEC 60204 | Safety of Machinery |

| IEC 60364 | Low Voltage Electrical Installations |

| IEC 60228 | Conductors of Insulated Cables |

| IEC 60287 | Electric Cables – Calculation of the Current Rating |

| IEC 60331 | Tests for Electric Cables Under Fire Conditions |

| IEC 60332 | Tests on Electric and Optical Fibre Cables Under Fire Conditions |

| IEC 60446 | Basic and safety principles for man-machine interface, marking and identification – Identification of equipment terminals, conductor terminations and conductors |

| IEC 60085 | Electrical Insulation – Thermal Evaluation and Designation. |

| IEC 60502 | Power cables with extruded insulation and their accessories for rated voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) |

| IEC 60668 | Dimensions of panel areas and cut-outs for panel and rack-mounted industrial- process measurement and control instruments |

| IEC 60529 | Degrees of Protection Provided by Enclosures (IP code) |

| IEC 60598 | Luminaires |

| IEC 60664 | Insulation Coordination For Equipment Within Low Voltage Systems |

| IEC 60751 | Industrial Platinum Resistance Thermometers and Platinum Temperature Sensors |

| IEC 61000 | Electromagnetic Compatibility (EMC) |

| IEC 61537 | Cable Management – Cable Tray Systems and Cable Ladder Systems |

| IEC 61557 | Electrical Safety in low voltage distribution systems up to 1000 V a.c. and 1500 V d.c. – Equipment for testing, measuring or monitoring of protective measures |

| IEC 62271-202 | High-voltage switchgear and controlgear – Part 202: High-voltage/low voltage prefabricated substation |

Standards applicable to UPS to be used in the system are as follows;

| IEC 60038 | IEC Standard Voltages |

| IEC 60364 | Low Voltage Electrical Installations |

| IEC 60439 | Low Voltage Switchgear and Controlgear Assemblies |

| IEC 60445 | Basic and safety principles for man-machine interface, marking and identification – Identification of equipment terminals and conductor terminations |

| IEC 60446 | Basic and Safety Principles for Man-Machine Interface, Marking and Identification – Identification of Conductors by Colors or Numerals |

| IEC 60529 | Classification of degrees of protection of enclosures |

| IEC 60146 | Semiconductor Converters |

| IEC 60947 | Low Voltage Switchgear and Controlgear |

| IEC 62259 | Stationary batteries – Nickel- cadmium – Partial recombination type |

| IEC 61000 | Electromagnetic Compatibility (EMC) – Various Parts |

| IEC 61557 | Electrical safety in low voltage distribution system up to 1000V A.C. and 1500V D.C. |

| IEC 62040-1-1 | Uninterruptible power systems (UPS) – General and safety requirements for UPS used in operator access areas |

| IEC 62040-1-2 | Uninterruptible power systems (UPS) – General and safety requirements for UPS used in restricted access locations |

| IEC 62040-2 | Uninterruptible power systems (UPS) – Electromagnetic compatibility (EMC) requirements |

| IEC 62040-3 | Uninterruptible power systems (UPS) – Method of specifying the performance and test requirements |

| ISO 9001 | Quality systems – Model for quality assurance in design, development, production, installation and servicing |

Standards applicable to transformer to be used in the system;

| IEC 60038 | IEC Standard Voltages |

| IEC 60044 | Instrument Transformers |

| IEC 60051 | Direct acting indicating analogue electrical measuring instruments and their accessories |

| IEC 60060 | High voltage test techniques |

| IEC 60073 | Basic and Safety Principles for Man-Machine Interface, Marking and Identification – Coding Principles for Indicators and Actuators |

| IEC 60076 | Power Transformers |

| IEC 60085 | Electrical insulation – Thermal evaluation and designation |

| IEC 60214 | Tap Changers |

| IEC 60255 | Measuring Relays and Protection Equipment |

| IEC 60269 | Low Voltage Fuses |

| IEC 60364 | Low Voltage Electrical Installations |

| IEC 60445 | Basic and safety principles for man-machine interface, marking and identification – Identification of equipment terminals, conductor terminations and conductor |

| IEC 60529 | Degrees of protection provided by enclosures (IP Code) |

| IEC 60616 | Terminal and tapping markings for power transformers |

| IEC 60617 | Graphic symbols for diagrams |

| IEC 60688 | Electrical measuring transducers for converting A.C. electrical quantities to analogue or digital signals |

| IEC 61000 | Electromagnetic compatibility (EMC) |

| ISO 887 | Plain washers for metric bolts, screws and nuts for general purposes – General plan |

| ANSIStd 32 | Standard Requirements, Terminology, and Test Procedure for Neutral Grounding Devices |

Standards applicable to manufacturing and assembly of LV distribution and MCC switchboards;

| IEC 60038 | IEC Standard Voltages |

| IEC 60044 | Instrument Transformers |

| IEC 60073 | Basic and Safety Principles for Man-Machine Interface, Marking and Identification – Coding Principles for Indication Devices and Actuators |

| IEC 60085 | Electrical insulation – Thermal evaluation and designation |

| IEC 60255 | Measuring Relays and Protection Equipment |

| IEC 60269 | Low Voltage Fuses |

| IEC 60364 | Low Voltage Electrical Installations |

| IEC 60439 | Low Voltage Switchgear and Controlgear Assemblies |

| IEC 60445 | Basic and safety principles for man-machine interface, marking and identification – Identification of equipment terminals and conductor terminations |

| IEC 60446 | Basic and Safety Principles for Man-Machine Interface, Marking and Identification – Identification of Conductors by Colors or Numerals |

| IEC 60529 | Classification of degrees of protection of enclosures |

| IEC 60617 | Graphical Symbols For Diagrams |

| IEC 60715 | Dimensions of LV Switchgear and Controlgear |

| IEC 60947 | Low voltage switchgear and controlgear |

| IEC 61000 | Electromagnetic Compatibility (EMC) – Various Parts |

| IEC 61459 | Low Voltage Fuses – Coordination Between Fuses and Contactors / Motor Starters – Application Guide |

| IEC 61557 | Electrical safety in low voltage distribution system up to 1000V A.C. and 1500V D.C. |

| IEC 61850 | Communications Networks and Systems in Substations |

| ISO 887 | Plain washers for metric bolts, screws and nuts for general purposes – General plan |

Standards applicable to MV Cubicles;

| IEC 62271-100 | High Voltage AC Circuit Breakers |

| IEC 62271-102 | AC Disconnectors and Earthing switches |

| IEC 62271-103 | High Voltage Switches |

| IEC 60282-1 | High Voltage Fuses |

| IEC 62271-200 | High-voltage switchgear and controlgear – Part 200: A.C. metal-enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV |

| IEC 62271-105 | High-voltage switchgear and controlgear – Part 105: Alternating current switch- fuse combinations |

| IEC 60529 | Degrees of Protection Provided by Enclosures (IP Code) |

| IEC 62271-1 | High-voltage switchgear and controlgear – Part 1: Common specifications |

SECTIONS OF MV & LV DISTRIBUTION KIOSKS

MV Section

In MV/LV distribution kiosks produced for Oil & Gas facilities, gas insulated MV cells are used in order to minimize the MV room dimensions and with the thought that the conductivity of the insulating air will cause problems. Under the MV room, there is a cable compartment at a height to provide the bending radius of the MV cable. The cells in the MV room and the MV busbar are supplied with energy from the energy transmission line located nearby, and the MV/LV transformer in the kiosk – the pump and other systems fed from the MV in the field.

3.2 Transformer Section

It is the section where the MV/LV transformer is located. Depending on the specification, hermetic or dry type transformers are used in the system. Technically speaking, hermetic transformer is preferred because it provides better insulation against harmful gases contained in the environment. The cooling of the transformer is done automatically with the HVAC system by constantly controlling the ambient temperature. MV and LV connections of the transformer are made with special cable heads in accordance with the standards. Cable passages from the cable compartment at the bottom of the room to the transformer are also specially designed.

3.3 LV Section;

LV room houses the LV main distribution and MCC switchboard, HVAC control panel and UPS control and distribution switchboard. Cooling of this section is also provided automatically via HVAC system that continuously monitors the room temperature. LV switchboard is manufactured as type-tested withdrawable in 3D form. Cable entries to all switchboards are provided from the bottom.

3.4 Battery Section;

This is the section that houses batteries that supply UPS system and DC control voltage. Cable connections are also provided from the bottom in this room. Outgoing battery cables are routed to the adjacent UPS switchboard and LV distribution switchboard. Some of the batteries supply the emergency lighting system.

Plant lighting and power outlet systems are designed as “exproof” and must be manufactured so as to prevent electrical sparkling in all the equipment.

4. CONCLUSION:

MV/LV distribution kiosks to be used in Oil & Gas plants must be designed as exproof. Since conductivity of insulation air is higher than the other environments, air-insulated system is not used for the selected MV cubicles. Transformers are hermetic or dry type with insulation systems and the transformer room is completely insulated from the external environment. LV main distribution and MCC switchboards are requested as type-tested withdrawable in 3D form. UPS system should be capable of supplying the plant for 1 hour at the desired rating. HVAC system allows cooling and heating independent from the external environment. Automatic fire detection and suppression systems with CO2 ensure protection against fire.

Compact MV/LV kiosks are manufactured to provide power distribution in Oil & Gas industry under electrically adverse environmental conditions.

5. REFERNCES

2. Specifications drafted by PETRONAS for kiosks in oil and gas plants.

3. Specifications drafted by ENI IRAK b.v. for kiosks in oil and gas plants.

4. “ELECTRICAL ENGINEERING GUIDELINES” used by Shell.

İsmail Atilla, Technic Sales Support Manager Aktif Elektroteknik