The International Arc Test for the SMC 46 kV Metal-Clad Switchgear Successfully Completed

- Introduction – From Design to Proven Safety

In modern medium-voltage (MV) networks, safety and service continuity are non-negotiable. For utilities, industrial plants and critical infrastructure, a single failure inside a switchgear panel can lead to severe equipment damage, long outages and, in the worst case, risks to personnel standing nearby.

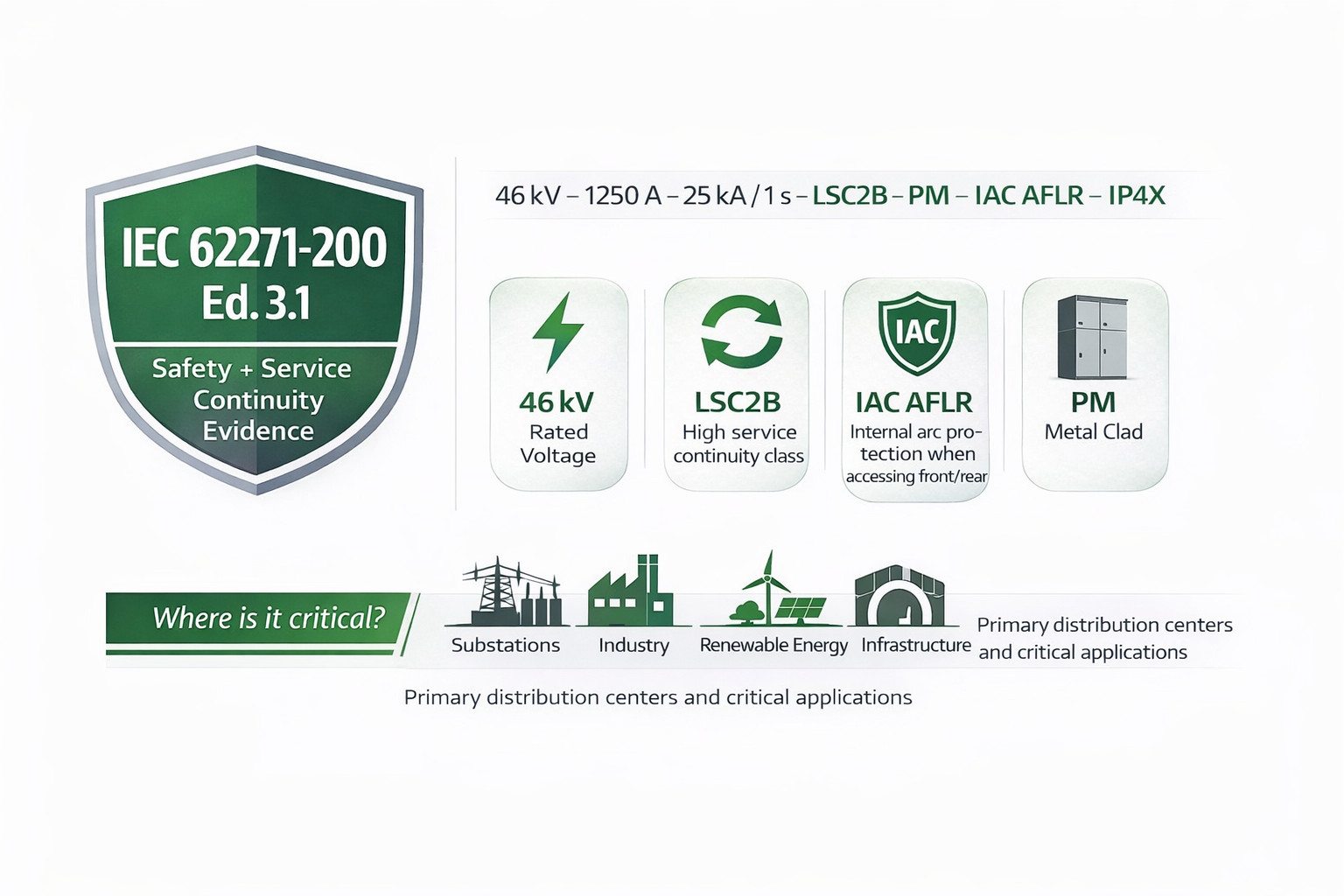

To address this, Aktif Elektroteknik has completed a comprehensive internal arc type test programme for its SMC metal-clad medium-voltage switchgear at KEMA Labs (CESI), Milan, in accordance with IEC 62271-200 Ed. 3.1. The tested SMC panels achieved the classification:

46 kV – 1250 A – 25 kA / 1 s – LSC2B – PM – IAC AFLR – IP4X, confirming that the design provides high service continuity and operator safety under worst-case internal arc fault conditions.

This blog explains what internal arc testing is, why it matters, and how each of the three tested compartments – cable, circuit-breaker and busbar – performed in the laboratory. You will also be able to watch video footage from each stage of the test to see how the SMC switchgear behaves under extreme stress.

- What Is an Internal Arc Fault – and Why Does It Matter?

An internal arc fault occurs when an unintended arc is created inside the switchgear enclosure – for example due to insulation failure, contamination, incorrect wiring, mechanical damage or human error. Even though such events are rare, the energy released in a medium-voltage panel can be enormous, producing intense heat, pressure waves, molten metal and hot gases in milliseconds.

Internal arc type tests are designed as “worst-case scenario simulations”. Instead of waiting for an accident in the field, a controlled arc is intentionally created in the laboratory at a specified current and duration (in our case, 25 kA for 1 second) to prove that:

- The enclosure contains the arc and hot gases in a controlled way,

- Operators standing in front, at the sides or at the rear are protected,

- The switchgear structure remains mechanically robust.

Passing these tests is therefore not just a formality – it is a strong, evidence-based statement about how the switchgear behaves when something goes wrong inside.

- The Standard Behind the Test: IEC 62271-200 Ed. 3.1

All tests for the SMC metal-clad switchgear were performed according to IEC 62271-200 Ed. 3.1, the latest edition of the international standard for AC metal-enclosed switchgear and controlgear.

The resulting classification string:

46 kV – 1250 A – 25 kA / 1 s – LSC2B – PM – IAC AFLR – IP4X

can be understood as follows:

- 46 kV – rated voltage

- 1250 A – rated continuous current

- 25 kA / 1 s – rated short-time withstand and internal arc test current/duration

- LSC2B – high level of Loss of Service Continuity, allowing some sections to remain energized while others are isolated

- PM – metal-clad partitions between compartments

- IAC AFLR – internal arc classification for operators at Access level, protected at Front, Lateral (sides) and Rear

- IP4X – degree of protection against ingress of solid objects

This combination is especially relevant for primary distribution switchgear in demanding environments, where both safety and availability must be proven, not just specified.

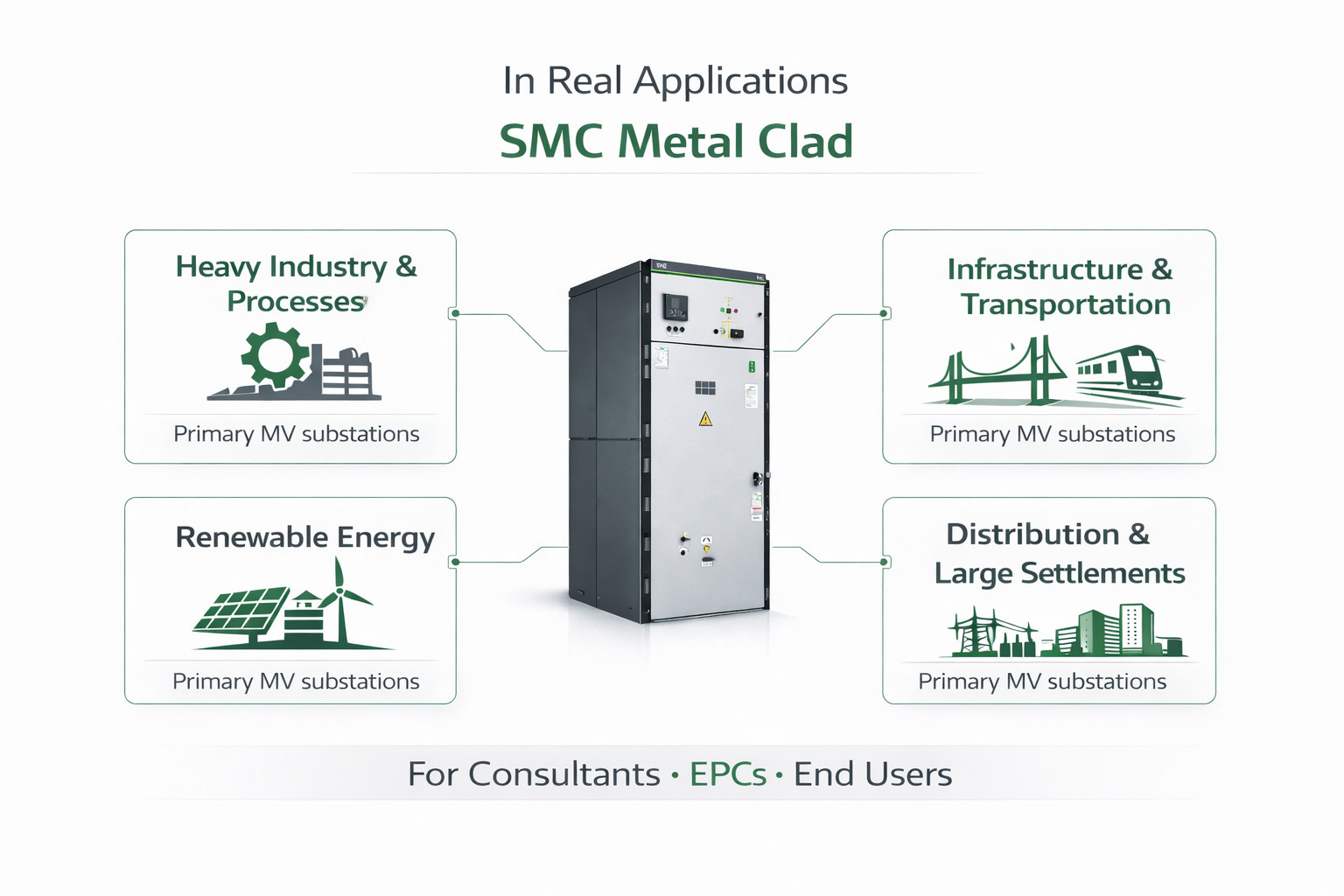

- SMC Metal-Clad Switchgear in Real Applications

SMC metal-clad switchgear is designed for primary MV substations in:

- Heavy and process industries,

- Infrastructure and transportation,

- Renewable energy plants,

- Utilities and large campuses.

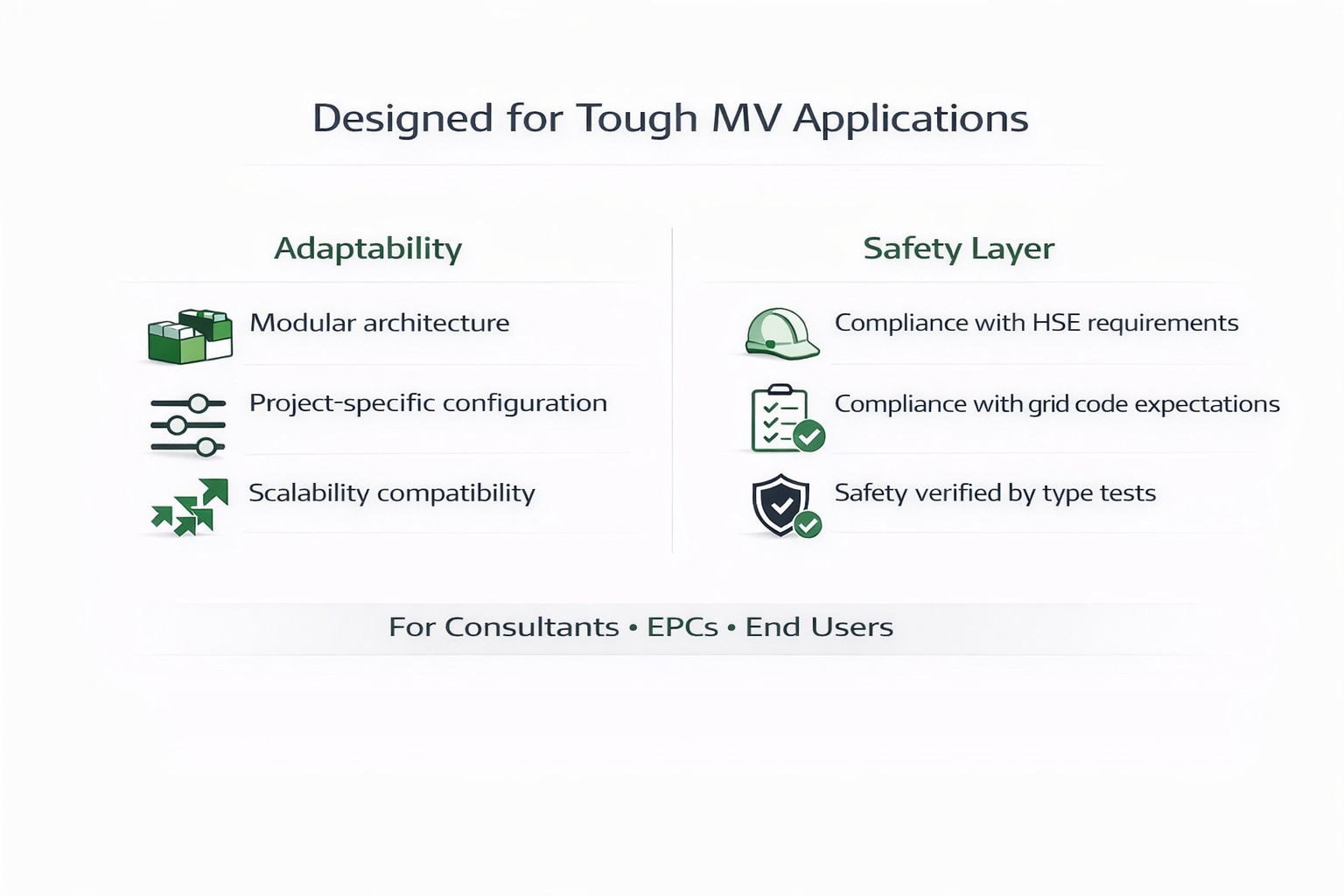

With a modular architecture and tailor-made configuration options, SMC panels can be adapted to project-specific layouts, protection schemes and future expansion needs. Internal arc certification adds an extra layer of confidence for consultants, EPCs and end users who must demonstrate compliance with stringent HSE and grid-code requirements.

- How Internal Arc Testing Is Performed

Before any arc is ignited, the test panel is prepared in a way that closely mimics real operation:

- All doors and covers are closed and latched

- Indicator fabrics are placed at defined positions on the outside

- Instrumentation and high-speed cameras are installed

- The test current and duration are set according to the standard (25 kA / 1 s)

An internal arc is then initiated at a defined location inside the relevant compartment. During and after the test, specialists evaluate:

- Flame and gas behaviour,

- Whether any doors or covers open unexpectedly,

- Whether fragments or parts are ejected,

- Whether visible openings or holes appear,

- The condition of the indicator fabrics,

- The continuity of the earthing system.

In this blog, you can follow three separate videos – one for each compartment – to see how the SMC switchgear manages the internal arc in the cable, circuit-breaker and busbar areas.

- Stage 1 – Cable Compartment Internal Arc Test

In the cable compartment, the internal arc represents a fault at or near the cable terminations – one of the most common practical risk areas. In the video, you will see a powerful flash and pressure build-up inside the lower section of the panel.

For this stage, the focus is on:

- Ensuring no dangerous fragments are ejected towards the operator area,

- Confirming that doors and covers remain closed,

- Verifying that hot gases are channelled towards dedicated exhaust paths.

The successful result demonstrates that, even if a severe cable-side fault occurs, the SMC metal-clad design helps protect both personnel standing in front of the panel and adjacent equipment.

Stage 2 – Circuit-Breaker Compartment Internal Arc Test

>The circuit-breaker compartment is the heart of the switching function. It is also an area where operators interact with the equipment during racking in/out, inspection or maintenance.

In this stage, the test simulates an internal arc fault within the CB compartment. The evaluation focuses on:

- The behaviour of the front mechanism door and inspection covers,

- The integrity of the moving parts region,

- Protection of the operator standing directly in front of the panel.

The SMC switchgear successfully managed the internal arc in this compartment, which is particularly reassuring for scenarios involving frequent switching, maintenance operations and high-duty cycles.

Stage 3 – Busbar Compartment Internal Arc Test

An internal arc in the busbar compartment is often considered a worst-case scenario, because the busbar system feeds multiple outgoing feeders and sections. A failure here can potentially affect a larger part of the network.

During the busbar compartment test, the SMC metal-clad panel is subjected to the same 25 kA / 1 s arc fault, now located in the upper busbar area. The video shows how the enclosure and pressure relief system handle this event without compromising the areas where operators may be present.

The successful outcome confirms that the SMC design offers a high level of protection, even under severe faults that involve the main busbar system.

- The Five IEC Internal Arc Criteria – Translated into Real Benefits

According to IEC 62271-200, internal arc tests must verify five key safety criteria. For SMC switchgear, all of them were fulfilled in all three compartments:

- No dangerous doors or covers opening → the structure remains intact.

- No ejection of heavy or dangerous fragments → reduced risk of injury.

- No holes or openings at defined heights → hot gases and arc products stay inside controlled paths.

- No ignition of indicator fabrics → gases are directed away from operator zones.

- Earthing integrity maintained → the fault current path remains controlled.

For the end user, these points translate into higher personnel safety, improved availability and easier compliance with internal safety policies and external regulations.

- Engineering Culture at Aktif Elektroteknik

For Aktif Elektroteknik, the SMC internal arc test is not a one-off milestone, but part of a broader engineering philosophy:

- Tailor-made designs based on project requirements,

- Type tests to validate critical performance aspects,

- Factory Acceptance Tests (FAT) to verify each delivery,

- Continuous feedback from the field into R&D and production.

By successfully completing the internal arc test programme, AE reinforces its commitment to safety, reliability and long-term partnerships in medium-voltage power distribution.

- Conclusion

The SMC metal-clad switchgear from Aktif Elektroteknik has now proven, under independent laboratory conditions, that it can withstand severe internal arc faults in the cable, circuit-breaker and busbar compartments, in line with the latest IEC 62271-200 Ed. 3.1 requirements.

For consultants, EPCs and end users planning new substations or retrofit projects, this means a switchgear platform that combines type-tested safety, service continuity and tailor-made engineering.

👉 Request a project-specific quotation or technical consultation:

Switching Life to Infinity.