Temperature and humidity in electrical panel environments are critical for system continuity and safety. Sudden temperature drops cause humidity to condense into water (dew point), leading to insulation failures in equipment. Panel heaters prevent these risks.

It is determined that condensation is unavoidable in the areas where the relative humidity is above 65%. The water that is gaseous state in the hot air is not to be in the gaseous state when the ambient temperature decreases and it converts into water droplets in liquid form. The heat caused by the nominal current flowing through the electrical equipment shall be increased by an external heater to prevent this issue. The temperature inside the cubicle shall be increased by 10 °C to keep the humidity in gas form. The design and type of the panel heater is crucial to accomplishing this task. In order for the air to heat up quickly enough to resist the sudden drop in temperature, heaters with an aluminum body with increased surface area and wrapped in stainless wire with a low resistance value change with temperature should be used. Aktif brand anti-condensation heaters are designed to provide these features.

According to the general acceptance that we can recommend, a 100 W anti-condensation heater is sufficient for a 1 m³ panel when choosing anti-condensation heater power. This value may need to be increased for geographical conditions or environments where humidity is high.

Anticondensation Heater Selection and Application

A heater with a capacity of 1 cm³ / W is required for providing air suitable for the panel as per international standards. In such case, a 100 W heater will be sufficient for a 1 m³ panel. This can be increased where the humidity is high.

The anti-condensation heater will function more efficiently if installed to the bottom of the panel due to convection of the hot air and entering the humid air from the ventilation holes.

The anti-condensation heaters shall not be closer than 10 cm to the electrical materials which can be affected by high temperature. The thermostat shall not be also closer than 10 cm to the anti-condensation heater.

Advantages

- The most efficient body surface area for space heating is achieved through enhanced extrusion and anodizing.

- The casing of Aktif heaters provides 120% higher surface efficiency compared to stainless steel tubular heaters.

- High thermal conductivity and electrical insulation magnesium oxide (MGO) powder is used as the insulation material.

- The use of stainless steel resistance wire with a low temperature-resistance coefficient ensures that the heater’s power does not decrease during operation.

- PTC heaters cannot prevent condensation as their power significantly decreases during operation.

- Aktif heaters offer the best solution for moisture reduction, being 60% more efficient than tubular heaters and 670% more efficient than PTC heaters.

- For panel heaters to perform their function uniformly, it is important to evenly distribute heat within the enclosure. The temperature difference across various points in the enclosure is a maximum of 20°C for the heaters.

- The moisture reduction rate of panel heaters must exceed the rate of sudden temperature drops. Aktif panel heaters are designed to meet this requirement with their structural and electrical features.

Applications Areas

- LV and HV Electrical Panels

Technical Specifications

| Resistance Element | : Stainless steel wire wound |

| Frame Profile | : High cooling surface aluminum |

| Insulation | : 2 kV 50/60 Hz 1 min. |

| Protection Degree | : IP5X |

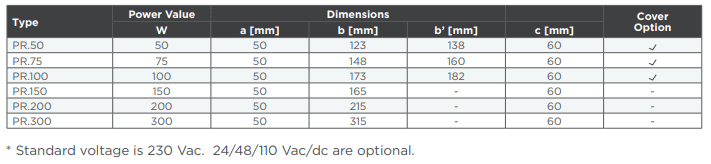

| Installation | : Screw mounting DIN 35 rail mounting |

| Touch-Safe Cover | : Optional |

Standards

- IEC 60664-1

- IEC 60529