Quality Management and Customer Relationship Management

Contents

Nowadays, the customer relationship management (CRM) has an important role for the companies. To compete instrumentally, sectors must focus on the customer experience. The goal of customer relationship management is to enhance relationships with customers and build customer loyalty. The effectiveness of CRM can be measured as a satisfaction level achieved.

This article’s aim is to define the latest trends in quality management in small and medium companies. Also, this paper clarified the quality management models based on wishes, needs and expectations of customers and its differences to the original concept of quality such as quality control, quality assurance and monitoring.

One of the hottest strategies is transforming companies to become customer-centric in today and their aim is to provide products or service that meet the requirements of customers. Quality management is based on customer expectations. If the product or service fulfill the customer requirements, we successfully satisfy the customer. Therefore, our customer become our partners and they can find a place at our process. Tight connection occurs between Customer Relation Management and Quality Management.

This article examines the Quality Management System and Total Quality Management Models, this models advantages and disadvantages and their differences and evaluations.

This paper also includes the Balanced Score Card Models with four perspectives; Financial Perspective, Customer Perspective, Internal Process Perspective, Learning and Growth Perspective.

Controlling the Quality Cost’s aim is to define real costs related with the quality systems and additional costs with the poor quality. This article explains the Quality Costs with four categories; Prevention Cost, Appraisal Cost, Internal Failure Cost and External Failure Cost.

QUALITY MANAGEMENT

Approaches to quality management developed in the past and we usually distinguish four stages of qualitative trends in companies [1]:

- Quality monitoring (so-called consecutive control, testing of samples of finished products);

- Quality control (so-called causal control, testing throughout the whole manufacturing process, with a focus on weak points and corrective measures);

- Quality assurance (QMS models – Quality Management System);

- Total quality management (TQM models – Total Quality Management).

While the first two stages are already completely inadequate tools of quality management in a hypercompetitive environment, the TQM and QMS models are generally considered as the basic systems in the modern concept of corporate management. In small and medium-sized companies QMS and TQM can be applied individually and collectively, even when QMS becomes a part of TQM. BSC models (Balanced Score Card) have an increasingly important role in quality management and can be applied to business management alone or as a part of TQM [2].

QMS Models

QMS (Quality Management System) offers a systematic approach to quality management. The system should be [1]:

- a written plan;

- a system ensuring the fulfillment of customers’ expectations in terms of the required quality;

- a system ensuring that all system requirements of the company are satisfied;

- a system valid for all business activities

Most companies have implemented QMS through the so-called ISO standards, a set of global standards that offers a pre-defined framework on which companies can build a quality management system [2].

The abbreviation “ISO” means that the system complies with the International Organization for Standardization that records and registers all standards. ISO standards require that companies describe in writing what they are doing, have done and will do to improve quality. It is necessary to mention all company operational procedures, to explain how quality is managed, monitored, recorded and checked [2]:

Benefits of implementation of the QMS models [2]:

| the management of the company has defined and introduced a system of rules at many levels of business activities; |

| the credibility of the company significantly increases, many foreign clients and consumers perceive a quality certificate holder as trustworthy, some clients (especially customers in industrial markets) even require the quality certificate from their supplier; |

| other involved parties (banks, investors, employees, etc.) also perceive the quality certificate as an element of stability; |

| Implementation of a quality policy in the company and receiving a quality certificate (especially from a reputable certification authority) is undoubtedly a competitive advantage. |

Disadvantages of certification according to QMS (ISO) standards [2]:

| relatively bureaucratic; |

| time consuming and expensive as it involves paying a certification authority and a consultant; we invest in employees through training of internal auditors, etc., but especially the growing implementation time is consuming the working time of individual employees who could spend it more efficiently; |

| It does not necessarily guarantee the quality of the product or service provided. |

TQM (Total Quality Management) Models

TQM (Total Quality Management) is a business and management philosophy based on promotion of the quality and management practices that lead to the global quality of the company [3].

It is generally accepted that the contemporary TQM literature evolved from works of ‘gurus’ such as Deming, Juran, Feigenbaum and Crosby, but there is not only one standard definition of TQM. A few of the definitions found in the literature are as follows [4]:

- According to Sashkin and Kiser, ‘TQM means the organization’s culture is defined and supports the consistent attainment of customer satisfaction through an integrated system of tools, techniques, and training. This involves the continuous improvement of organizational processes, resulting in highquality products and services’ [5]

- ‘TQM is an approach to managing organizations which emphasizes the continuous improvement of quality and customer satisfaction, entails the application of systematic tools and approaches for managing organizational processes with these ends in mind, and involves the establishment of structures such as quality improvement teams and councils for maintaining focus on these ends and enacting organizational improvement processes’ [6]

- [7] defines the term TQM as:

‘Total = everyone associated with the company is involved in continuous improvement (including its customers and suppliers if feasible),

Quality = customers’ expressed and implied requirements are met fully,

Management = executives are fully committed’.

An analysis of these definitions suggests that, after all, they are not very different [4].

We assume that the total quality of the company and of our products is influenced not only by those who are in permanent contact with our customers, i.e. traders and marketers, but also people who are involved in other activities, processes and projects. The TQM model and philosophy puts these aspects into direct correlation with the quality expected by a customer. [2]

The TQM model is based on [1]:

- a company is a team of people;

- any business activity has an impact on quality;

- suppliers are an integral part of the quality system;

- we asses quality from the perspective of customers and consumers

While the QMS models are perceived rather as quality assurance for the customer (manufacturing, product and sales concepts), the TQM philosophy is seen in reverse, i.e. in terms of the requirements and needs of customers with regards to our business (CRM – Customer Relationship Management). While we can imagine QMS as a possible part of the marketing transaction (one-time sale), TQM dominates the relational (long-term) approach to customers. From the perspective of the marketing mix, a shift can be perceived from a mix of factors known as 4P (Product – Price – Place – Promotion), seen from the perspective of the company, to innovative factors 4C (Customers Wants and Needs Cost to the Customers – Convenience – Communication), seen from the customer’s perspective [8]

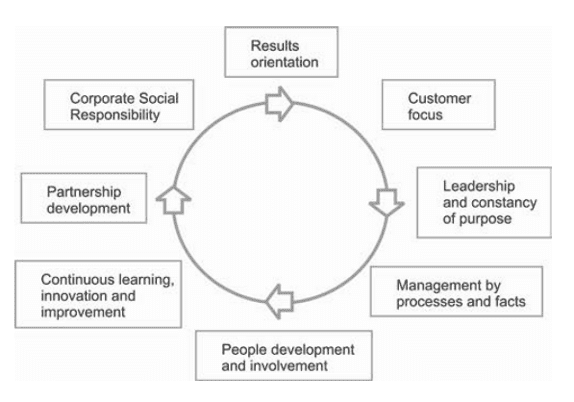

Although the TQM system originated in the United States, it has become very popular in Japan. A Japanese TQM model was regarded for many years as an example of the modern quality management system. It is based on four pillars of quality perception (Figure 1) and became a quality management model for many global corporations [2].

![Figure 1. Japanese Model TQM [2]](https://aktif.net/wp-content/uploads/2021/07/1.jpg)

| TQM | QMS | |

| Description | A strategy of constant

improvement of all company activities are involved |

A norm assuring customers that the

company can reach the guaranteed quality level |

| Characteristics | Comparable approach

including all company activities and employees |

Methodological approach

to quality |

| Driving Force | People | Procedures |

| Target | To constantly improve quality and satisfy customer’s needs | To get certificate and compliance with

specifications |

| Culture | Quality assures a competitive advantage only when every

employee is involved |

To hold firm to written

procedures and their observance |

Figure 2. Differences between the TQM and QMS approaches to evaluation of quality [1]

While the QMS models are currently very popular in small and medium sized companies, the TQM models are implemented in large transnational corporations. Auditing and certification companies have understandably attempted to introduce TQM into small companies. If there is a properly implemented and observed QMS model, it is usually sufficient for smaller companies. On the contrary, QMS is practically unusable for large multinational companies, because they create their own systems that fit their corporate culture, mission and vision while respecting geographical differences [2].

Balanced Scorecard Models (BSC Models)

The BSC was originally developed as a performance measurement system in 1992 by Dr. Robert Kaplan and Dr. David Norton at the Harvard Business School. Unlike earlier performance measurement systems, the BSC measures performance across a number of different perspectives—a financial perspective, a customer perspective, an internal business process perspective, and an innovation and learning perspective [9].

The BSC’s four perspectives can be characterized briefly as follows [12]

- The financial perspective indicates whether the transformation of a strategy leads to improved economic success. Thus, the financial measures assume a double role. On one hand, they define the financial performance a strategy is expected to achieve. On the other hand, they are the endpoint of cause and effect relationships referring to the other BSC perspectives [12].

- The customer perspective defines the customer/market segments in which the business competes. By means of appropriate strategic objectives, measure, targets and initiatives the customer value proposition is represented in the customer perspective through which the firm/business unit wants to achieve a competitive advantage in the envisaged market segments [12].

- The internal process perspective identifies those internal business processes that enable the firm to meet the expectations of customers in the target markets and those of the shareholders [12].

- Finally, the learning and growth perspective describes the infrastructure necessary for the achievement of the objectives of the other three perspectives. In this case, the most important areas are qualification, motivation and goal orientation of employees, and information systems [12].

The purpose of a BSC is to formulate a hierarchic system of strategic objectives in the four perspectives, derived from the business strategy and aligned towards the financial perspective. Based on such a causal system of objectives, corresponding measures are formulated in all four perspectives [12].

As in the CRM model, the involved parties (stakeholders and shareholders) must find a compromise with all groups that impact the company and as in the BSC model all of these strategic activities must be continuously optimized and their balance managed [2].

Evaluation of TQM

If it is decided to implement the TQM model, an optimum model must be selected. It is also possible to use some commonly used TQM models, such as the EFQM (European Foundation Quality Management) model. It is one of the most popular models, sometimes called an excellent production model, but rather the EFQM excellence model. It is a model developed by the European Foundation for Quality Management. EFQM is often regarded as a general guideline for implementation of the quality models based on TQM. It is based on five conditions and four areas of evaluation of results (Figure 5) [2].

The EFQM Excellence Model is based on the accepting and consistent realizing in everyday practice “Eight Basic Rules of Excellence” – that is adapted to the European conditions, the principles of the Total Quality Management (TQM), which implemented in the strategic management process guarantee the success of the enterprise, its development and strengthening of the market position [14]

Evaluation of BSC

BSC controlling is focused on finding optimal evaluation criteria for the individual areas of the BSC model. The basic condition for the efficient use of BSC in responsible management is to provide information to identify tasks, performance measurement and evaluation in individual areas [10].

Evaluation of QMS

Focuses on the management of deviations from quality targets, fulfillment of the documents contained in the quality guidelines and other controlled documents forming the framework of quality management. As in the financial controlling of small and medium-sized companies, a natural controller is a bank providing operating loans (the tool is a financial analysis in the form of predetermined covenants). In quality controlling the certification authority takes on the role of a controller – in the first phase the certification authority issues a quality certificate, then reissues it in predetermined periods (usually 1-2 years), which is done based on achievement of the given standards. This requires that the company continually maintains the set quality management system (QMS), which may be done by its employees (managers responsible for quality) or by external consultants. Their task is to continuously monitor and evaluate the implementation of standards, quality targets and quality policy using the controlled documents usually contained in the so-called quality guidelines. This phase of the controlling is thus partly managed by a quality manager, or a consultant or a certification authority. However, this must be preceded by primary controlling activities of an operational nature, consisting in the selection of a consultant, an initial audit, implementation of the quality system and selection of a certification authority [2].

Quality Costs

Quality costs are important cost items that in accordance with the growing importance of the quality and implementation of the quality management systems may ultimately have a significant impact on overall results [2].

Controlling the Quality Cost’s aim is to define real costs related with the quality systems and additional costs with the poor quality [15].

Quality cost divided into the following three categories [15]:

Prevention Cost

The costs of all activities specially designed to prevent poor quality in products or services.

We can classify prevention costs as follows [15]:

- Marketing Customer User

- Product/ Service/design Development

- Purchasing Prevention Cost

- Operation (Manufacture or Service) Prevention Cost

- Quality Administration

Appraisal Cost

The cost associated with measuring, evaluating or auditing products or services to assure conformance to quality standards and performance requirements [15].

We can classify appraisal costs as follows [15]:

- Purchasing Appraisal Cost

- Operation (Manufacture or Service) Appraisal Cost

- External Appraisal Cost

- Review of Test and Inspection Data

- Miscellaneous Quality Evaluations

Failure Cost

The costs resulting from products or services not conforming to to requirements or customer /user needs. Failure costs are divided into internal and external failure cost categories [15].

Internal Failure Cost

Failure costs occurring prior to delivery or shipment of the product, or furnishing of a service, to the customer. Examples are the costs of scrap, rework, reinspection, retesting, material review and down grading [15].

We can classify internal failure costs as follows [15]:

- Product/Service Design Failure Cost

- Purchasing Failure Cost

- Operation (Manufacture or Service) Failure Cost.

External Failure Costs

Failure costs occurring after delivery or shipment of the product, and during or after furnishing of a service, to the customer. Examples are the costs of processing, customer complaints, customer returns, warranty claims and product recalls [15].

We can classify external failure costs as follows [15]:

- Complaint Investigations/Customer or User Service

- Returned Goods

- Retrofit Costs

- Warranty Claims

- Liability Costs

- Penalties

- Customer/user Goodwill

- Lost Sales

Conclusion

Customer relationship management (CRM) has become one of the leading business strategies in the recent years. The effectiveness of CRM can be measured and also can be seen on the customer satisfaction level. We can say that product quality was very popular in previous years but nowadays process quality is very popular and effect the all management system. Modern quality management textbooks have even introduced a new term: CRMQ – Customer Relationship Management and Quality. The results of performance measurement for companies show that activities and outcomes related with customer is becoming important. BSC treats the customer as one of four perspectives, CRM technologies are increasingly used in a BSC evaluation. On the other hand, small and medium companies quality management systems are related with the standards including in the QMS and also approach based on the TQM related with the satisfaction of customer. Satisfying the customer is important but it is not more important than the overall efficiency of the company. That is why measurement, evaluation and control methods are extremely important for quality.

REFERENCES

[1] Frame, A., Barnes, D., Edwards, Ch., 2001, “Managing Customers Relations and Quality”, Book 1, 2, 3, 4, (OUBS, Milton Keynes). [2] Havlicek, K., Breckova, P., & Zampeta, V. (2013). Quality Management as a Part of CRM.Ho, S . K., 1997, Are ISO 9000 and TQM routes for logistics excellence? Logistics Information Management, 10, 275–283.

[3] Bovée, C.L, Thill J.V., 1992: Marketing. New York, Mc.Graw-Hill 1992. [4] Jung, J. Y., & Wang, Y. J. (2006). Relationship between total quality management (TQM) and continuous improvement of international project management (CIIPM). Technovation, 26(5-6), 716-722. [5] Partlow, C. G., 1996, Human-resources practices of TQM hotels. Cornell Hotel and Restaurant Administration Quarterly, October, 67–77 [6] Mohrman, S . A., Tenkasi, R. V., Lawler, E. E., and Ledford, G. E., 1995, Total quality management: practice and outcomes in the largest US firms. Employee Relations, 17, 26–41 [7] Ho, J. T. (1997). Corporate wellness programmes in Singapore: Effect on stress, satisfaction and absenteeism. Journal of Managerial Psychology. [8] Kašík, M., Havlíček, K., 2009, “Role of Marketing in Strategy Management”,(University of Finance and Administration, Eupress, Prague). [9] Johnson, C. C., Beiman, I., & Thompson, J. (2007). Balanced Scorecard: for State-owned Enterprises: Driving Performance and Corporate Governance. Asian Development Bank. [10] Král, B. et al., 2010, “Management Accounting. Third updated edition”, (Management Press, Prague). [11] Havlíček, K., 2009, “Role of Managers in Company Management”, (University of Finance and Administration, Eupress, Prague). [12] Figge, F., Hahn, T., Schaltegger, S., & Wagner, M. (2002). The sustainability balanced scorecard–linking sustainability management to business strategy. Business strategy and the Environment, 11(5), 269-284. [13] Kaplan, R. S., & Norton, D. P. (2000). Putting the Balanced Scorecard to work. Boston, Mass.: Harvard Business Review OnPoint. [14] Michalska, J. (2008). Using the EFQM excellence model to the process assessment. Journal of Achievements in Materials and Manufacturing Engineering, 27(2), 203-206. [15] Campanella, J. (1999). Principles of quality costs: Principles, implementation, and use. In ASQ World Conference on Quality and Improvement Proceedings (p. 507). American Society for Quality.