Description

Static VAr Compensation (SVC) applications which are necessary for melt shops which use arc furnaces for melting process. Static VAr Compensation systems are high tech applications which solve harmonic, flicker and reactive power compensation problems in plant.

Static VAr Compensators are designed to decrease power quality problems caused by rapidly changing active and reactive power and switching non-linear components like thyristors. The SVC system can keep bus voltage practically at a constant level.

The SVC system also reduces unexpected stops and expensive restart procedures. The benefit of SVC can be notice that a constant power factor even despite of the variable reactive power in an industrial plant. Compensation and improving the quality of power increases the capacity of active power transmission and reduces energy consumption. Due to the fact network overload can be avoided consequently electrical power is consumed efficiently facility as well as regionally.

Significant benefits of SVC systems are; flicker reduction, voltage stabilization, reactive power compensation, power factor improvement, increased voltage on the load bus, reduction of harmonics, rise of efficiency, positive effect on the consumption of electrodes, heat losses and the lifetime of the furnace’s inside lining, short return on investment period ( 1-2 years).

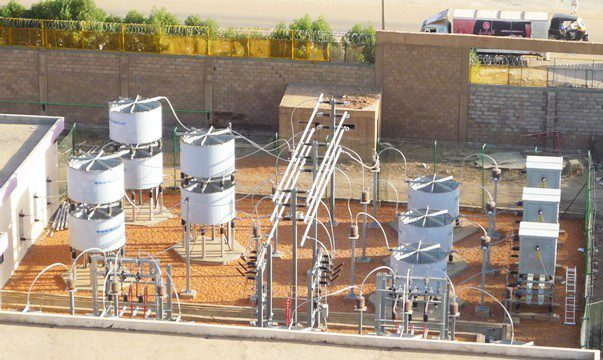

24 MVAr SVC Project has installed by experienced Aktif Group Power Quality department at Hightec Steel Co. (Khartoum – Sudan) that is an iron steel factory which has arc furnace.