The Importance of Insulation Monitoring Devices IT Systems

As far as the safety of the power supply is concerned, the IT system offers the most advantages. . For this reason, many areas are used where the maximum reliability and safety of the power source is required. IT systems used in isolation monitoring systems are increasingly being used in many different energy systems because an unforeseen failure of the power supply can cause serious costs.

More Information: Isolated Power Panels

Advanced information through insulation monitoring

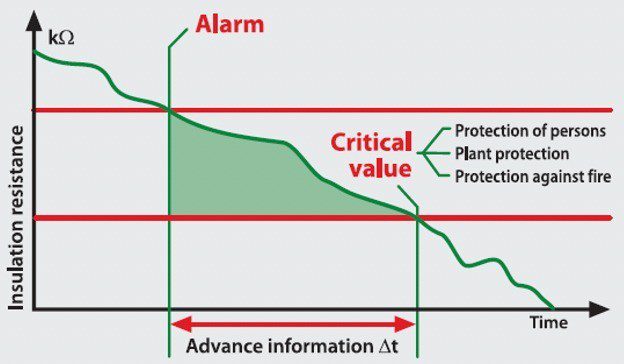

According to IEC 60364-4-41, an IT system must always be equipped with an insulation monitoring device. The insulation monitoring device, which is connected between the active conductors and earth, superimposes a DC measuring voltage onto the system. On the occurrence of an insulation fault, the measuring circuit between system and earth closes via the insulation fault RF, so that a DC measuring current Im proportionate to the insulation fault is produced. This DC measuring current causes a voltage drop which is evaluated by the electronic circuitry. If this voltage drop exceeds a certain value, which is proportional to the insulation resistance, an indication is given via alarm LEDs and alarm contacts. The small sys- tem leakage capacitances Ce existing in the system are only charged to the value of the measuring DC voltage and do not influence the measurement after the brief transient response. A detailed description of the requirements for an insulation monitoring device is given in IEC 62557-8: 1998-05. Thanks to the insulation monitoring device, the operator of the electrical installation is pro- vided with the necessary advance information which gives him effective support for preventive maintenance measures (figure 5).

Modern measuring principles for modern electrical loads

The measuring principle described before, can be used when the connected loads exclusively are AC consumers. However, recently there had been changes in the structure of the electrical loads. In many cases there are drives or loads with switched-mode power supplies (e. g. personal computers, electronic control gear). Whilst on the one hand there are the advantages of limited power loss, smaller dimensions, and less weight, on the other hand problems may arise through harmonic components caused by switched-mode power supply units and influence by DC leakage current. Insulation monitoring devices using the measuring principle of super- imposed measuring DC voltage may cause false alarms due to DC components. The reason for that is that in case of a fault these extraneous voltages occur additionally to the measuring voltage and therefore either lead to an increased measuring current and hence to increased response sensitivity or lead to lower measuring current what means that tripping is prevented (figure 6).

High system leakage capacitances, which often exist in the form of interference suppressor filters (EMC) between system and the earth, are also a source of interferences for insulation monitoring devices with DC measuring voltage. When switching the IT system on, for the DC measuring voltage these capacitances represent a low-ohmic connection to the earth so that a high measuring DC current (load current for Ce) will flow which results in an alarm message through the insulation monitoring device.

In order to eliminate this influence on the insulation measurement caused by DC measuring voltages and system leakage capacitances, modern insulation monitoring devices work with a pulsed measuring voltage. This measuring principle responds to system leakage capacitances with variable clock times, taking the load curve of Ce into consideration. The value of the occurring extraneous DC voltages is determined within one measuring cycle and in this way can be considered accordingly when the insulation resistance is detected. In practice, that means that neither extraneous DC voltages nor high system leakage capacitances can no longer influence the measuring results and in this way allow precise determination of the insulation resistance. The latest, international standard IEC 61557-8: 1998-05 specifies the requirements for insulation monitoring de- vices which are used in systems up to AC 1000 V and DC 1500 V, independent of the measuring principle.

In order to fulfil the requirements of modern power supplies with regard to electrical safety and operating continuity, new insulation monitoring devices have been developed. The new AMPPlus measuring principle allows determining the insulation resistance precisely, even in extended systems and in systems with variable- speed drives. Comprehensive information about the current state of the electrical installation via text display guarantees the necessary advance information. Besides, there is the possibility of transferring measuring data via the communication bus to higher-level systems or of filing measuring data in a memory, in order to register events including date and time.

Another version which can be extended to a complete insulation fault location system is available, allowing time and cost-saving location of faulty circuits.

Result

According to DIN VDE 0100-410 and IEC 60364-4-41, insulation monitoring devices are an absolutely essential component of unearthed power supplies (IT systems) in order to report a first fault between a live part and an exposed-conductive part or to earth.

References

[1] Bender Technical aspects Main catalogue Part 1[2] W. Hofheinz: Protective measures with insulation monitoring, 2nd Edition

Harun Öndül- Sales Manager – Aktif Mühendislik

eren One Comment

MIGUEL ROSALES

says:Do you have an insulation Monitor with communication port?

With Pulse for fault detector?For disconnected systems?

What do you have for e-mobility chargers?

Do you have some products for the Hospital Market?